PAGE 7 Putting it all back together:

Back to page 6 HERE

Everything worked it’s way up to the painting… Now that’s done. So time to reassemble the Tracker. I made sure to let the paint cure for a day or so before messing with it. Now we need the door handles back.. And some of the other bits.. Oh did I forget to mention that blue is my favorite color ! This is “techno blue” from late 90’s VWs. The more I look at it the more I really like it.

The Blue & Black color scheme I’ve gone with looks very good. You can start to see that once I put stuff back on.. Like the tail light and spare holder. And don’t forget that nice handle.. So this almost completes the tailgate.

Once the inner panel was installed.. with the proper push pins that I sourced out of China.. we are done.

Check one thing now off the list. The weather stripping and door gaskets are done. The sill covers are on. And the door switches are in and tested.. Working! and I bet that’s the first time they worked for a long time.

Jan 12 2016:

A bit of a snag.. the carpet … of which I spent a few hours vacuuming. Still has crap coming out and stinks. I’m at the point where I need to install the carpet or do exterior stuff. At one point I thought of buying new carpet. But it is over $300. And it’s still has to be cut and fitted. I’m trying to keep costs down. So I’m going to pressure wash the carpet and strip all the stinky old padding off the back. That means I would have to go get some underlay for carpet to replace the padding.. but at least it all would be clean. Soooo while the carpet dries I’ll turn my attention to the bumpers, grill and the bush guard. I can flip back and forth.. and Git R Done.

While I was washing the carpet , I gave the seats a shampoo. Here they are back in the basement drying out. Notice the seat bolsters are black and the uppers are grey. We could not match that grey. So had to use black. I could not afford to change the backs too, so that’s a compromise.

I removed the front plastic from the bumper. And found that the metal was in great shape.

It makes it easier to design and modify the bush guard I have from a big truck to fit the tiny Tracker. I also want strong steel ears coming off the frame for attaching a tow bar.. or maybe even a plow. Got to think it over.. In the meantime I painted the rear bumper cover and mounted it back in place.

The back of the Tracker is now finished. That roll you see is the under felt for the interior. Yet to do is cutting and fitting it into place.

Done ! Got the carpet back in today. And the dash, center consoles and seats.

Left the horn cover off.. cause I may have to adjust the wheel.

The Bush Guard:

If you look back you will see that whom ever installed the winch just cut away enough of the bumper cover to bolt the winch to the steel part. That worked ok.. just ok. I had this bush guard from a full size truck. Fairly fancy one too.

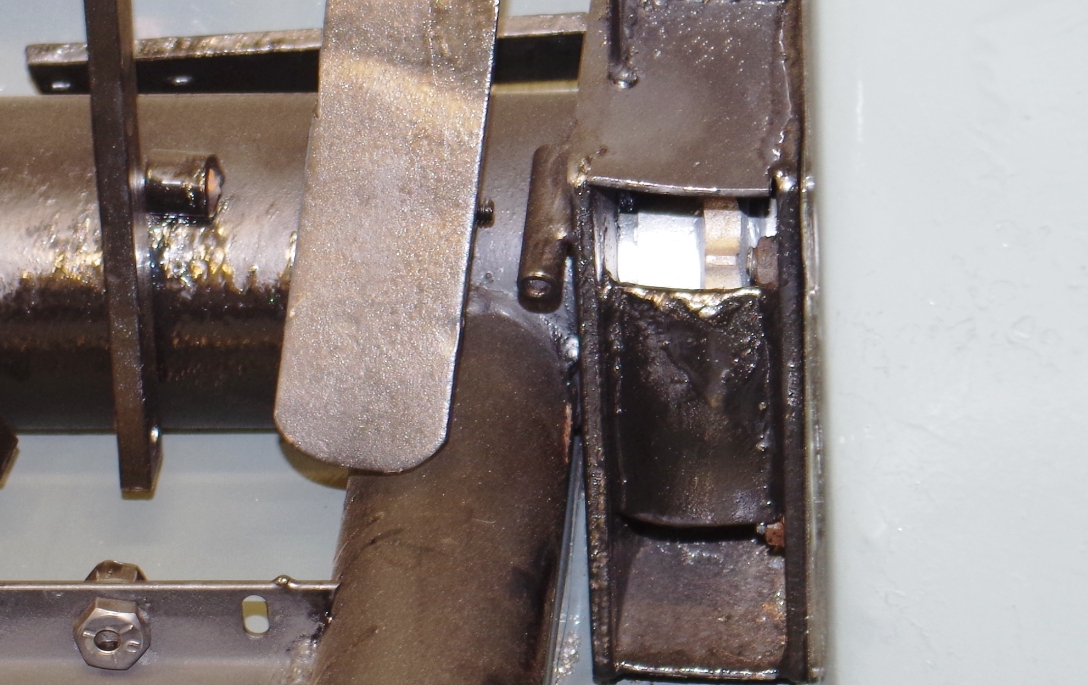

Way too heavy for the little Tracker though. So I’ve removed the headlight guards, trimmed 6 inches out of the middle and shortened the height by 8 inches. That removed the bottom tube and about half the weight. Now I have a great flat surface for the new winch. (mounting plate in photo). Brackets to hold the guard and winch are welded to the bumper.

The bumper is quite strong, so this will work good. I’ve painted the guard and set it aside. Also today I set to work welding and fabricating the ears for attachments.

These are 3/4 solid steel , welded to the frame and braced. I moved the tow hook to the center to free up the end of the left side frame. And of coarse everything got a satin black paint job. Time now to cut and fit the bumper cover..

There ! The covers come right up to the bush guard. looks great. And as my very special added bonus.. LED running lights. !

Fitted right into the bumper ! These even light up orange with the turn lights. Cool ! Now for the paint and install.

Jan 24 2016:

Yesterday I painted all the front grill / bumper parts… Today I got everything installed and the wiring done.

I love it when a plan comes together… Everything fit and worked out great. The winch loves it’s new home.. the wires are neatly run .. I couldn’t be more pleased.

The control box is under this plate.. hiding. There is two wireless remotes for the winch.. all working great.

Time for another page.. most likely the last.. Cause there’s not much left to do.

Page 8