March 2017:

Rebuilding the TUB

I have a great way of dealing with the bulge of the chain run that plagues the underside of all Terra Jets. In the case of this one it hangs a further two inches below the bottom at the rear axle. And that makes it vulnerable to hitting rocks … and therefore making a hole …that lets the water in ! Can’t have that. Nope.. And I don’t want to be repairing that after I have gone to this much trouble. My solution:

Add the two inches right across the back.. and cap it with 1/8 ” plate steel. Ha ! take that rock ! This also makes a good sump for the bilge pump, and changes the curve at the rear.. ( stern )

This is just the test fit.. but I’ll be welding these new 3/16 ” thick sides to the frame.

Done.. Also have to think ahead to what will be needed and easier to install now.. like the brake holder. Two small pieces to stiffen the 1/8 bottom plate too.. and a quick paint job on the underside.. Next…

I tacked the 1/8 th plate into place.. so I could flip the tub over. and weld up some of the holes..

There was lots of those holes.. It’s a good thing the tub won’t have to win any beauty contests. But I’m wanting it strong and leak proof not pretty. Things have to work with the other parts though.. Like the body needs to seal to the top of the tub.

So I’m rebuilding parts like these front corners. I will test fit the body too.. And other considerations like the fuel tank , the seat and the battery holder. They all need good mounting .

This is the tank from an Argo.. It’s nice and flat.. but still two inches higher then where the seat was.. Is a higher seat a problem ? will have to think on this one. In the mean time I cut the welds ( they were bad anyway) on the seat supports. I want them bolted through the tub …no welds. With this setup the tank will be hidden under the seat.. Once things are going together I’ll test out seat locations.

I brought the body in for a test fit.. and to see how things line up. I’m going to build a winch mount on the front bumper ..and need to know how far back it can go.. And also the sides need to fit in the running boards.. Got it figured out. Almost all holes are filled in the tub. Just two more big patches.. and the bottom can go on.

One down.. one to go. This was a big flap cut into the front .. Not the tidiest welding.. but strong.. Time to get the bottom done. lots of careful welding to do.

Well that was NOT easy.. We used straps and blocks to get the bend in the bottom.. That 18 Ga sheet will not bend easy. The small transition piece had to be heated and hammered into submission. But it’s done except the curved piece for the back… I’m thinking a press will be of help there. And here’s a new short video .. part 2:

I’m taking a few days off to heal up my eye.. got something in there and was finding it hard to see detail..

Back at it.. and I got all the welding done on the tub.

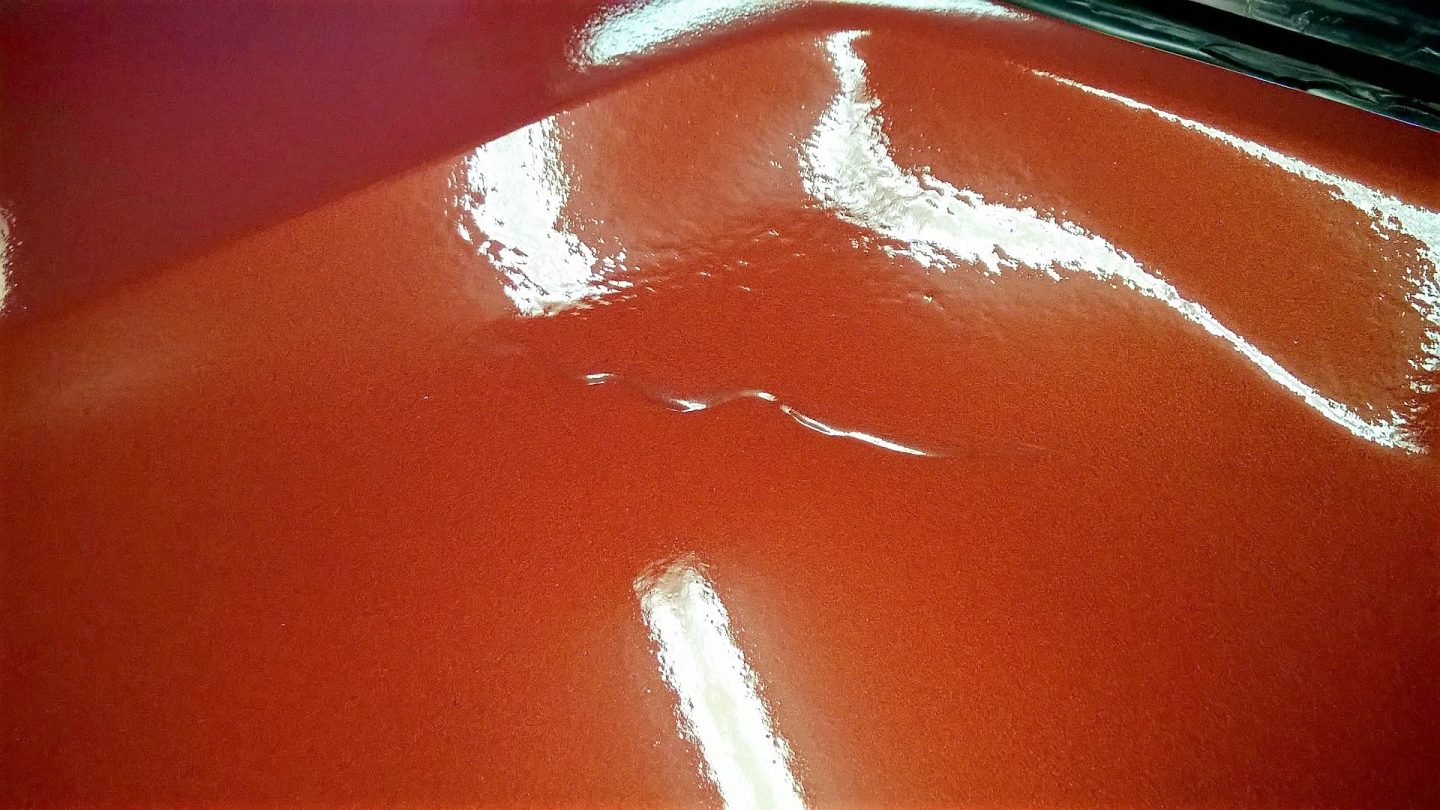

Here we go.. the rear is done.. even have a new drain plug. The next step is applying the box liner finish.. And it’s time to start another page..

Continued on Page 3

Or back to Page 1